So,I have been looking into the Hemp issue,and came across this classic. It in combination with other material I have read on the subject,leads me to the belief that the whole marijuana argument as put forth by the State, is nothing more then a Straw man's argument to steer attention away from just why the 1937 Marijuana Tax Law was passed,and who benefited from Hemp's suppression.

It makes absolutely no sense that this 'wonder' plant, which could actually revive and cleanse the Earth is sitting unused,while we continue to allow them to pollute the Earth with their man made garbage.Plastic's being the worse.This plant ALONE could jump start the People in this country to great heights and away from this destructive globalism that these good for nothing politicians have sold the land into,we need to take the land back,and rebirth it, in a different image.More to come on this,take care all....

The Emperor Wears No Clothes

Chapter 1

Overview of the

History of Cannabis Hemp

For the Purpose of Clarity in this Book: Explanations or documentations

marked with an asterisk (*) are listed at the end of the related paragraph(s). For

brevity, other sources for facts, anecdotes, histories, studies, etc., are cited in

the body of the text or included in the appendices. The facts cited herein are

generally verifiable in the Encyclopedia Britannica, which was printed

primarily on paper produced with cannabis hemp for over 150 years. However,

any encyclopedia (no matter how old) or good dictionary will do for general

verification purposes.

Cannabis Sativa L.

Also known as: Hemp, cannabis hemp, Indian (India) hemp, true hemp,

muggles, weed, pot, marijuana, reefer, grass, ganja, bhang, "the kind," dagga,

herb, etc., all names for exactly the same plant!

What's in a Name? (U.S. Geography)

HEMPstead, Long Island; HEMPstead County, Arkansas; HEMPstead, Texas;

HEMPhill, North Carolina; HEMPfield, Pennsylvania, among others, were

named after cannabis growing regions, or after family names derived from

hemp growing.

American Historical Notes

In 1619, America's first marijuana law was enacted at Jamestown Colony,

Virginia, "ordering" all farmers to "make tryal of" (grow) Indian hempseed.

More mandatory (must-grow) hemp cultivation laws were enacted in

Massachusetts in 1631, in Connecticut in 1632 and in the Chesapeake

Colonies into the mid-1700's.

Even in England, the much-sought-after prize of full British citizenship was

bestowed by a decree of the crown on foreigners who would grow cannabis,

and fines were often levied against those who refused.

Cannabis hemp was legal tender (money) in most of the Americas from 1631

until the early 1800's. Why? To encourage American farmers to grow more.1

You could pay your taxes with cannabis hemp throughout America for over

200 years.2

You could even be jailed in America for not growing cannabis during several

periods of shortage, e.g., in Virginia between 1763 and 1767. (Herndon, G.M.,

Hemp in Colonial Virginia, 1963; The Chesapeake Colonies, 1954;

L.A.Times, August 12, 1981; et al.)

George Washington and Thomas Jefferson grew cannabis on their plantations.

Jefferson,3 while envoy to France, went to great expense - and even

considerable risk to himself and his secret agents - to procure particularly

good hemp seeds smuggled illegally into Turkey from China. The Chinese

Mandarins (political rulers) so valued their hemp seed that they made its

exportation a capital offense.

The United States Census of 1850 counted 8,327 hemp "plantations"*

(minimum 2,000-acre farm) growing cannabis hemp for cloth, canvas and

even the cordage used for baling cotton. Most of these plantations were

located in the South or in the border states, primarily because of the cheap

slave labor available prior to 1865 for the labor-intensive hemp industry.

(U.S. Census, 1850; Allen, James Lane, The Reign of Law, A Tale of the

Kentucky Hemp Fields, MacMillan Co., NY, 1900; Roffman, Roger, Ph.D.

Marijuana as Medicine, Mendrone Books, WA, 1982.)

*This figure does not include the tens of thousands of smaller farms

growing cannabis, nor the hundreds of thousands - if not millions - of

family hemp patches in America; nor does it take into account that well into

this century 80 percent of America's hemp consumption for 200 years still

had to be imported from Russia, Hungary, Czechoslovakia and Poland, etc.

Benjamin Franklin started one of America's first paper mills with cannabis.

This allowed America to have a free colonial press without having to beg or

justify the need for paper and books from England.

In addition, various marijuana and hashish extracts were the first, second or

third most- prescribed medicines in the United States from 1842 until the

1890's. It's medicinal use continued legally through the 1930's for humans and

figured even more prominently in American and world veterinary medicines

during this time.

Cannabis extract medicines were produced by Eli Lilly, Parke-Davis, Tildens,

Brothers Smith (Smith Brothers), Squibb and many other American and

European companies and apothecaries. During all the time there was not one

reported death from cannabis extract medicines, and virtually no abuse or

mental disorders reported, except for first-time or novice users occasionally

becoming disoriented or overly introverted.

(Mikuriya, Tod, M.D., Marijuana Medical Papers, Medi-Comp Press, CA;

Cohen, Sidney & Stillman, Richard, Therapeutic Potential of Marijuana,

Plenum Press, Ny, 1976.)

World Historical Notes

"The earliest known woven fabric was apparently of hemp, which began to be

worked in the eight millennium (8,000 - 7,000 B.C.)" (The Columbia History

of the World, 1981, page 54.)

The body of literature (i.e., archaeology, anthropology, philology, economy,

history) pertaining to hemp is in general agreement that, at the very least:

From more than 1,000 years before the time of Christ until 1883 A.D.,

cannabis hemp - indeed, marijuana - was our planet's largest agricultural crop

and most important industry, involving thousands of products and enterprises;

producing the overall majority of Earth's fiber, fabric, lighting oil, paper,

incense and medicines. In addition, it was a primary source of essential food

oil and protein for humans and animals.

According to virtually every anthropologist and university in the world,

marijuana was also used in most of our religions and cults as one of the seven

or so most widely used mood-, mind-, or pain-altering drugs when taken as

psychotropic, psychedelic (mind-manifesting or -expanding) sacraments.

Almost without exception, these sacred (drug) experiences inspired our

superstitions, amulets, talismans, religions, prayers, and language codes. (See

chapter 10 on "Religions and Magic.")

(Wasson, R., Gordon, Soma, Divine Mushroom of Immortality; Allegro, J.M.,

Sacred Mushrooms & the Cross, Doubleday, NY, 1969; Pliny; Josephus;

Herodotus; Dead Sea Scrolls; Gnostic Gospels; the Bible; Ginsberg Legends

Kaballah, c. 1860; Paracelsus; British Museum; Budge; Ency. Britannica,,

"Pharmacological Cults;" Schultes & Wasson, Plants of the Gods, Research

of R.E. Schultes, Harvard Botanical Dept.; Wm EmBoden, Cal State U.,

Northridge; et al.)

Great Wars were Fought to

Ensure the Availability of Hemp

For example, the primary reason for the War of 1812 (fought by America

against Great Britain) was access to Russian cannabis hemp. Russian hemp

was also the principal reason that Napoleon (our 1812 ally) and his

"Continental Systems" allies invaded Russia in 1812. (See Chapter 12, "The

(Hemp) War of 1812 and Napolean Invades Russia.")

In 1942, after the Japanese invasion of the Philippines cut off the supply of

Manila (Abaca) hemp, the U.S. Government distributed 400,000 pounds of

cannabis seeds to American farmers from Wisconsin to Kentucky, who

produced 42,000 tons of hemp fiber annually until 1946 when the war ended.

Why Has Cannabis

Hemp/Marijuana

Been So Important in History?

Because cannabis hemp is, overall, the strongest, most-durable, longest-lasting

natural soft-fiber on the planet. Its leaves and flower tops (marijuana) were -

depending on the culture - the first, second or third most important and most used

medicines for two-thirds of the world's people for at least 3,000 years,

until the turn of the century.

Botanically, hemp is member of the most advanced plant family on Earth. It is

a dioecious (having male, female and sometimes hermaphroditic - male and

female on the same plant), woody, herbaceous annual that uses the sun more

efficiently than virtually any other plant on our planet, reaching a robust 12 to

20 feet or more in one short growing season. It can be grown in virtually any

climate or soil condition on Earth, even marginal ones.

Hemp is, by far, Earth's premier, renewable natural resource. This is why hemp

is so very important.

Chapter 2

A Brief Summary of

the Uses of Hemp

Our Challenge to the World:

Try to Prove Us Wrong!

If all fossil fuels and their derivatives, as well as trees for paper and

construction were banned in order to save the planet, reverse the Greenhouse

Effect and stop deforestation;

Then there is only one known annual renewable natural resource that is

capable of providing the overall majority of the world's paper and textiles;

meeting all of the world's transportation, industrial and home energy needs;

simultaneously reducing pollution, rebuilding the soil, and cleaning the

atmosphere all at the same time...

And that substance is - the same one that did it all before -

Cannabis Hemp...Marijuana!

Ships and Sailors

Ninety percent* of all ships' sails (since before the Phoenicians, from at least

the 5th Century B.C. until long after the invention and commercialization of

steam ships - mid- to late-19th century) were made from hemp.

*The other 10% were usually flax or minor fibers like ramie, sisal, jute, abaca.

(Abel, Ernest, Marijuana: The First 12,000 Years, Plenum Press, 1980;

Herodotus, Histories, 5th Century B.C.; Frazier, Jack, The Marijuana Farmers,

1972; U.S. Agricultural Index, 1916-1982; USDA film, Hemp for Victory,

1942.)

The word "canvas" is the Dutch pronunciation (twice removed, from French

and Latin) of the Greek word "Kannabis."*

*Kannabis - of the (Hellenized) Mediterranean Basin Greek language, derived

from the Persian and earlier Northern Semitics (Quanuba, Kanabosm, Cana?,

Kanah?) which scholars have now traced back to the dawn of the 6,000-year old

Indo-Semitic-European language family base of the Sumerians and

Accadians. The early Sumerian/Babylonian word K(a)N(a)B(a), or Q(a)N(a)B

(a) is one of man's longest surviving root words.1 (KN means cane and B

means two - two reeds or two sexes.)

In addition to canvas sails, until this century virtually all of the rigging, anchor

ropes, cargo nets, fishing nets, flags, shrouds, and oakum (the main protection

for ships against salt water, used as a sealant between loose or green beams)

were made from the stalk of the marijuana plant.

Even the sailors' clothing, right down to the stitching in the seamen's rope soled

and (sometimes) "canvas" shoes, was crafted from cannabis.*

*An average cargo, clipper, whaler, or naval ship of the line, in the 16th, 17th,

18th, or 19th centuries carried 50 to 100 tons of cannabis hemp rigging, not to

mention the sails, nets, etc., and needed it all replaced every year or two, due to

salt rot. (Ask the U.S. Naval Academy, or see the construction of the USS

Constitution, a.k.a. "Old Ironsides," Boston Harbor.)

(Abel, Ernest, Marijuana, The First 12,000 Years, Plenum Press, 1980; Ency.

Brittanica; Magoun, Alexander, The Frigate Constitution, 1928; USDA film

Hemp for Victory, 1942.)

Additionally, the ships' charts, maps, logs, and Bibles were made from paper

containing hemp fiber from the time of Columbus (15th Century) util the

early 1900's in the Western European/American World, and by the Chinese

from the 1st Century A.D. on. Hemp paper lasted 50 to 100 times longer than

most preparations of papyrus, and was a hundred times easier and cheaper to

make.

Incredibly, it cost more for a ship's hempen sails, ropes, etc. than it did to build

the wooden parts.

Nor was hemp restricted to the briny deep...

Textiles & Fabrics

Until the 1820's in America (and until the 20th Century in most of the rest of

the world), 80 percent of all textiles and fabrics used for clothing, tents, bed

sheets and linens,* rugs, drapes, quilts, towels, diapers, etc. - and even our

flag, "Old Glory," were principally made from fibers of cannabis.

For hundreds, if not thousands of years (until the 1830's), Ireland made the

finest linens and Italy made the world's finest cloth for clothing with hemp.

*The 1893-1910 editions of Encyclopedia Britannica indicate - and in 1938,

Popular Mechanics estimated - that at least half of all the material that has

been called linen was not made from flax, but from cannabis. Herodotus (c.

450 B.C.) describes the hempen garments made by the Thracians as equal to

linen in fineness and that "none but a very experienced person could tell

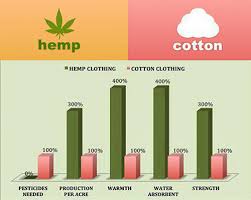

whether they were of hemp or flax."

Although these facts have been almost forgotten, our forebears were well

aware that hemp is softer than cotton, more water absorbent than cotton, has

three times the tensile strength of cotton and is many times more durable than

cotton.

In fact, when the patriotic, real-life, 1776 mothers of our present day blue blood

"Daughters of the American Revolution" (the DAR of Boston and New

England organized "spinning bees" to clothe Washington's soldiers, the

majority of the thread was spun from hemp fibers. Were it not for the

historically forgotten (or censored) and currently disparaged marijuana plant,

the Continental Army would have frozen to death at Valley Forge,

Pennsylvania.

The common use of hemp in the economy of the early republic was important

enough to occupy the time and thoughts of our first U.S. Treasury Secretary

Alexander Hamilton, who wrote in a Treasury notice from the 1790's, "Flax

and Hemp: Manufacturers of these articles have so much affinity to each

other, and they are so often blended, that they may with advantage be

considered in conjunction. Sailcloth should have 10% duty..."

(Herndon, G.M., Hemp in Colonial Virginia, 1963; DAR histories; Able

Ernest, Marijuana, the First 12,000 Years; also see the 1985 film Revolution

with Al Pacino.)

The covered wagons went west (to Kentucky, Indiana, Illinois, Oregon, and

California*) covered with sturdy hemp canvas tarpaulins,2 while ships sailed

around the "Horn" to San Francisco on hemp sails and ropes.

*The original, heavy-duty, famous Levi pants were made for the California

'49ers out of hempen sailcloth and rivets. This way the pockets wouldn't rip

when filled with gold panned from the sediment.3

Homespun cloth was almost always spun, by people all over the world, from

fibers grown in the "family hemp patch." In America, this tradition lasted from

the Pilgrims (1620's) until hemp's prohibition in the 1930's.*

*In the 1930's, Congress was told by the Federal Bureau of Narcotics that

many Polish-Americans still grew pot in their backyards to make their winter

"long johns" and work clothes, and greeted the agents with shotguns for

stealing their next year's clothes.

The age and density of the hemp patch influences fiber quality. If a farmer

wanted soft linen-quality fibers he would plant his cannabis close together.

As a rule of thumb, if you plant for medical or recreational use, you plant one

seed per five square yards. When planted for seed: four to five feet apart.

(Univ. of Kentucky Agricultural. Ext. leaflet, March 1943.)

One-hundred-twenty to one-hundred eighty seeds to the square yard are

planted for rough cordage or course cloth. Finest linen or lace is grown up to

400 plants to the square yard and harvested between 80 to 100 days.

(Farm Crop Reports, USDA international abstracts. CIBA Review 1961-62

Luigi Castellini, Milan Italy.)

By the late 1820's, the new American hand cotton gins (invented by Eli

Whitney in 1793) were largely replaced by European-made "industrial" looms

and cotton gins ("gin" is short for engine), because of Europe's primary

equipment-machinery-technology (tool and die making) lead over America.

Fifty percent of all chemicals used in American agriculture today are used in

cotton growing. Hemp needs no chemicals and has few weed or insect enemies

- except for the U.S.government and the DEA.

For the first time, light cotton clothing could be produced at less cost than

hand retting (rotting) and hand separating hemp fibers to be hand spun on

spinning wheels and jennys.4

However, because of its strength, softness, warmth and long-lasting qualities,

hemp continued to be the second most-used natural fiber* until the 1930's.

*In case you're wondering, there is no THC or "high" in hemp fiber. That's

right, you can't smoke your shirt! In fact, attempting to smoke hemp fabric - or

any fabric, for that matter - could be fatal!

After the 1937 Marijuana Tax law,new DuPont "plastic fibers," under license

since 1936 from the German company I.G. Farben (patent surrenders were part

of Germany's World War I reparation payments to America), replaced natural

hempen fibers. (Some 30% of I.G. Farben, under Hitler, was owned and

financed by America's DuPont.) DuPont also introduced Nylon (invented in

1935) to the market after they'd patented it in 1938.

(Colby, Jerry, DuPont Dynasties, Lyle Stewart, 1984.)

Finally, it must be noted that approximately 50% of all chemicals used in

American agriculture today are used in cotton growing. Hemp needs no

chemicals and has few weed or insect enemies - except for the U.S.

government and the DEA.

(Cavendar, Jim, Professor of Botany, Ohio University, "Authorities Examine

Pot Claims," Athens News, November 16, 1989.)

Fiber & Pulp Paper

Until 1883, from 75-90% of all paper in the world was made with cannabis

hemp fiber including that for books, Bibles, maps, paper money, stocks and

bonds, newspapers, etc. The Gutenberg Bible (in the 15th Century); Pantagruel

and the Herb pantagruelion, Rabelais (16th Century); King James Bible (17th

Century); the works of Fitz Hugh Ludlow, Mark Twain, Victor Hugo,

Alexander Dumas; Lewis Carroll's "Alice in Wonderland" (19th Century); and

just about everything else was printed on hemp paper.

The first draft of the Declaration of Independence (June 28, 1776) was written

on Dutch (hemp) paper, as was the second draft completed on July 2, 1776.

This was the document actually agreed to on that day and announced and

released on July 4, 1776. On July 19, 1776, Congress ordered the Declaration

be copied and engrossed on parchment (a prepared animal skin) and this was

the document actually signed by the delegates on August 2, 1776. Hemp paper

lasted 50 to 100 times longer than most preparations of papyrus, and was a

hundred times easier and cheaper to make.

What we (the colonial Americans) and the rest of the world used to make all our paper from was the discarded sails and ropes by ship owners as scrap for recycling into paper.

The rest of our paper came from our worn-out clothes, sheets, diapers, curtains and rags* sold to scrap dealers made primarily from hemp and sometimes flax.

*Hence the term "rag paper."

Our ancestors were too thrifty to just throw anything away, so, until the 1880's, any remaining scraps and clothes were mixed together and recycled into paper.

Rag paper, containing hemp fiber, is the highest quality and longest lasting

paper ever made. It can be torn when wet, but returns to its full strength when

dry. Barring extreme conditions, rag paper remains stable for centuries. It will

almost never wear out. Many U.S. government papers were written, by law, on

hempen "rag paper" until the 1920's.5

Rag paper, containing hemp fiber, is the highest quality and longest lasting

paper ever made. It can be torn when wet, but returns to its full strength when

dry. Barring extreme conditions, rag paper remains stable for centuries. It will

almost never wear out. Many U.S. government papers were written, by law, on

hempen "rag paper" until the 1920's.5

It is generally believed by scholars that the early Chinese knowledge, or art, of hemp paper making (1st Century A.D. - 800 years before Islam discovered how, and 1,200 to 1,400 years before Europe) was one of the two chief reasons that Oriental knowledge and science were vastly superior to that of the West for 1,400 years. Thus, the art of long-lasting hemp paper making allowed the Orientals' accumulated knowledge to be passed on, built upon, investigated, refined, challenged and changed, for generation after generation (in other words, cumulative and comprehensive scholarship).

The other reason that Oriental knowledge and science sustained superiority to that of the West for 1,400 years was that the Roman Catholic Church forbade reading and writing for 95% of Europe's people; in addition, they burned, hunted down, or prohibited all foreign or domestic books - including their own Bible! - for over 1,200 years under the penalty and often-used punishment of death. Hence, many historians term this period "The Dark Ages" (476 A.D. - 1000 A.D., or even until the Renaissance). (See Chapter 10 on Sociology.) [So the Dark Ages has origin in the Church,that sounds right to me D.C]

Thomas Paine outlined four essential natural resources for the new nation in Common Sense (1776); "cordage, iron, timber and tar."

Chief among these was hemp for cordage. He wrote, "Hemp flourishes even to rankness, we do not want for cordage." Then he went on to list the other essentials necessary for war with the British navy; cannons, gunpowder, etc.

From 70-90% of all rope, twine, and cordage was made from hemp until 1937. It was then replaced mostly by petrochemical fibers (owned principally by DuPont under license from Germany's I.G. Corporation patents) and by Manila (Abaca) Hemp, with steel cables often intertwined for strength - brought in from our "new" far-western Pacific Philippines possession, seized from Spain as reparation for the Spanish American War in 1898.

The paintings of Van Gogh, Gainsborough, Rembrandt, etc., were primarily painted on hemp canvas, as were practically all canvas paintings.

A strong, lustrous fiber, hemp withstands heat, mildew, insects and is not damaged by light. Oil paintings on hemp and/or flax canvas have stayed in fine condition for centuries.

*National Institute of Oilseed Products congressional testimony against the 1937 Marijuana Transfer Tax Law. As a comparison, consider that the U.S. Drug Enforcement Administration (DEA), along with all America's state and local police agencies, claim to have seized for all of 1996, 700+ tons of American-grown marijuana; seed, plant, root, dirt clum and all. Even the DEA itself admits that 94 to 97 percent of all marijuana/hemp plants that have been seized and destroyed since the 1960's were growing completely wild and could not have been smoked as marijuana.

Congress and the Treasury Department were assured through secret testimony given by DuPont in 1935-37 directly to Herman Oliphant, Chief Counsel for the Treasury Dept., that hempseed oil could be replaced with synthetic petrochemical oils made principally by DuPont.

Oliphant was solely responsible for drafting the Marijuana Tax Act that was submitted to Congress.9 (See complete story in Chapter 4, "The Last Days of Legal Cannabis.")

Hempseed oil lit the lamps of legendary Aladdin, Abraham the prophet, and in real life, Abraham Lincoln. It was the brightest lamp oil.

Hempseed oil for lamps was replaced by petroleum, kerosene, etc., after the 1859 Pennsylvania oil discovery and John D. Rockefeller's 1870-on national petroleum stewardship. (See chapter nine of "Economics.")

In fact, the celebrated botanist Luther Burbank stated, "The seed [of cannabis] is prized in other countries for its oil, and its neglect here illustrates the same wasteful use of our agricultural resources."

(Burbank, Luther, How Plants Are Trained To Work For Man, Useful Plants, P.F. Collier & Son Co., NY, Vol. 6, pg. 48.)

Biomass can be converted to methane, methanol or gasoline at a fraction of the current cost of oil, coal, or nuclear energy - especially when environmental costs are factored in - and its mandated use would end acid rain, end sulfur based smog, and reverse the Greenhouse Effect on our planet - right now!* *Government and oil and coal companies, etc., will insist that burning biomass fuels is no better than using up our fossil fuel reserves, as far as pollution goes; but this is patently untrue.

Why? Because, unlike fossil fuels, biomass comes from living (not extinct) plants that continue to remove carbon dioxide pollution from our atmosphere as they grow, through photosynthesis. Furthermore, biomass fuels do not contain sulfur.

This can be accomplished if hemp is grown for biomass and then converted through pyrolysis (charcoalizing) or biochemical composting into fuels to replace fossil fuel energy products.*

*Remarkably, when considered on a planet-wide, climate-wide, soil-wide basis, cannabis is at least four and possibly many more times richer in sustainable, renewable biomass/cellulose potential than its nearest rivals on the planet - cornstalks, sugarcane, kenaf trees, ect. (Solar Gas, 1980; Omni, 1983; Cornell University; Science Digest, 1983; etc.).

Also see Chapter 9 on "Economics."

One product of pyrolysis, methanol, is used today by most race cars and was used by American farmers and auto drivers routinely with petroleum/methanol options starting in the 1920's, through the 1930's, and even into the mid-1940's to run tens of thousands of auto, farm and military vehicles until the end of World War II.

Methanol can even be converted to a high-octane lead-free gasoline using a catalytic process developed by Georgia Tech University in conjunction with Mobil Oil Corporation.

As stated earlier, for at least 3,000 years, prior to 1842, widely varying marijuana extracts (buds, leaves, roots, etc.) were the most commonly used and widely accepted majority of mankind's illnesses.

However, in Western Europe, the Roman Catholic Church forbade use of cannabis or any medical treatment, except for alcohol or blood letting, for 1200-plus years. (See Chapter 10 on "Sociology.")

The U.S. Pharmacopoeia indicated that cannabis should be used for treating such ailments as: fatigue, fits of coughing, rheumatism, asthma, delirium tremens, migraine headaches and the cramps and depressions associated with menstruation.(Professor William EmBoden, Professor of Narcotic Botany, California State University, Northridge.)

Queen Victoria used cannabis resins for her menstrual cramps and PMS, and her reign (1837-1901) paralleled the enormous growth of the use of Indian cannabis medicine in the English-speaking world.

In this century, cannabis research has demonstrated therapeutic value - and complete safety - in the treatment of many health problems including asthma, glaucoma, nausea, tumors, epilepsy, infection, stress, migraines, anorexia, depression, rheumatism, arthritis and possible herpes. (See Chapter 7, "Therapeutic Uses of Cannabis.")

(See Rubin, Dr. Vera, "Research Institute for the Study of Man;" Eastern Orthodox Church; Cohen & Stillman, Therapeutic Potential of Marijuana, Plenum Press, 1976; Abel, Ernest, Marijuana, The First 12,000 Years, Plenum Press, NY, 1980; Encyclopedia Brittanica.)

Hempseed can be pressed for its highly nutritious vegetable oil, which contains the highest amount of essential fatty acids in the plant kingdom. These essential oils are responsible for our immune responses and clear the arteries of cholesterol and plaque.

The byproduct of pressing the oil from the seed is the highest quality protein see cake. It can be sprouted (malted) or ground and baked into cakes, breads and casseroles. Marijuana seed protein is one of mankind's finest, most complete and available-to-the-body vegetable proteins. Hempseed is the most complete single food source for human nutrition. (See discussion of edistins and essential fatty acids, Chapter 8.)

Hempseed was - until the 1937 prohibition law - the world's number-one bird seed, for both wild and domestic birds. It was their favorite* of any seed food on the planet; four million pounds of hempseed for songbirds were sold at retail in the U.S. in 1937. Birds will pick hempseeds out and eat them first from a pile of mixed seed. Birds in the world live longer and breed more with hempseed in their diet, using the oil for their feathers and their overall health. (More in Chapter 8, "Hemp as a Basic World Food.")

*Congressional testimony, 1937; "Song birds won't sing without it," the bird food companies told Congress. Result; sterilized cannabis seeds continue to be imported into the U.S. from Italy, China and other countries.

Hempseed produces no observable high for humans or birds. Only the most minute traces of THC are in the seed. Hempseed is also the favorite fish bait in Europe. Anglers buy pecks of hempseed at bait stores, then thrashing for the hempseed and are caught by hook. No other bait is as effective, making hempseed generally the most desirable and most nutritious food for humans, birds and fish.

(Jack Herer's personal research in Europe.) (Frazier, Jack, The Marijuana Farmers, Solar Age Press, New Orleans, LA, 1972)

*Dewey & Merrill, Bulletin #404, United States Dept. of Agriculture, 1916.

Practical, inexpensive fire-resistant construction material, with excellent thermal and sound-insulating qualities, is made by heating and compressing plant fibers to create strong construction paneling, replacing dry wall and plywood. William B. Conde of Conde's Redwood Lumber, Inc. near Eugene, Oregon, in conjunction with Washington State University (1991-1993), has demonstrated the superior strength, flexibility, and economy of hemp composite building materials compared to wood fiber, even as beams.

Isochanvre, a rediscovered French building material made from hemp hurds mixed with lime, actually petrifies into a mineral state and lasts for many centuries. Archeologists have found a bridge in the south of France, from the Merovingian period (500-751 A.D.), built with this process. (See Chenevotte habitat of Rene, France in Appendix I.)

Hemp has been used throughout history for carpet backing. Hemp fiber has potential in the manufacture of strong, rot resistant carpeting - eliminating the poisonous fumes of burning synthetic materials in a house or commercial fire, along with allergic reactions associated with new synthetic carpeting.

Plastic plumbing pipe (PVC pipes) can be manufactured using renewable hemp cellulose as the chemical feedstocks, replacing non-renewable coal or petroleum-based chemical feedstocks.

So we can envision a house of the future built, plumbed, painted and furnished with the world's number-one renewable resource - hemp.

Many artists and writers have used cannabis for creative stimulation - from the writers of the world's religious masterpieces to our most irreverent satirists. These include Lewis Carroll and his hookah- smoking caterpillar in Alice in Wonderland, plus Victor Hugo and Alexander Dumas; such jazz greats as Louis Armstrong, Cab Calloway, Duke Ellington and Gene Krupa; and the pattern continues right up to modern-day artists and musicians such as the Beatles, the Rolling Stones, the Eagles, the Doobie Brothers, Bob Marley, Jefferson Airplane, Willie Nelson, Buddy Rich, Country Joe & the Fish, Joe Walsh, David Carradine, David Bowie, Iggy Pop, Lola Falana, Hunter S. Thompson, Peter Tosh, the Grateful Dead, Cypress Hill, Sinead O'Connor, Black Crowes, etc.

Of course, smoking marijuana only enhances creativity for some and not for others.

But throughout history, various prohibition and "temperance" groups have attempted and occasionally succeeded in banning the preferred recreational substances of others, like alcohol, tobacco or cannabis.

Abraham Lincoln responded to this kind of repressive mentality in December, 1840, when he said:

"Prohibition . . . goes beyond the bounds of reason in that it attempts to control a man's appetite by legislation and makes a crime out of things that are not crimes . . . A prohibition law strikes a blow at the very principles upon which our government was founded.

It's time we put capitalism to the test and let the unrestricted market of supply and demand as well as "Green" ecologically consciousness decide the future of the planet.

A cotton shirt in 1776 cost $100 to $200, while a hemp shirt cost 50 cents to $1. By the 1830's, cooler, lighter cotton shirts were on par in price with the warmer, heavier, hempen shirts, providing a competitive choice.

People were able to choose their garments based upon the particular qualities they wanted in a fabric. Today we have no such choice.

The role of hemp and other natural fibers should be determined by the market of supply and demand and personal tastes and values, not by the undue influence of prohibition laws, federal subsidies and huge tariffs that keep the natural fabrics from replacing synthetic fibers.

Sixty years of government suppression of information has resulted in virtually no public knowledge of the incredible potential of the hemp fiber or its uses.

By using 100% hemp or mixing hemp with cotton, you will be able to pass on your shirts, pants and other clothing to your grandchildren. Intelligent spending could essentially replace the use of petrochemical synthetic fibers such as nylon and polyester with tougher, cheaper, cool, absorbent, breathing, biodegradable, natural fibers.

China, Italy and Eastern European countries such as Hungary, Romania, Czechoslovakia, Poland, and Russia currently make millions of dollars worth of sturdy hemp and hemp/cotton textiles - and could be making billions of dollars worth - annually.

These countries build upon their traditional farming and weaving skills, while the U.S. tries to force the extinction of this plant to prop up destructive synthetic technologies.

Even cannabis/cotton blend textiles were still not cleared for direct sale in the U.S. until 1991. The Chinese, for instance, were forced by tacit agreement to send us inferior ramie/cottons.

(National Import/Export Textile Company of Shangai, Personal communication with author, April and May, 1983.)

As the 1990 edition of The Emperor went to press, garments containing at least 55 percent cannabis hemp arrived from China and Hungary. In 1992, as we went to press, many different grades of 100 percent hemp fabric had arrived directly from China and Hungary. Now, in 1998, hemp fabric is in booming demand all over the world, arriving from Romania, Poland, Italy, Germany, et al. Hemp has been recognized as the hottest fabric of the 1990's by Rolling Stone, Time, Newsweek, Paper, Detour, Details, Mademoiselle, The New York Times, The Los Angeles Times, Der Spiegel, ad infinitum. All have run, over and over again, major stories on industrial and nutritional hemp.

Additionally, hemp grown for biomass could fuel a trillion-dollar per year energy industry, while improving air quality and distributing the wealth to rural areas and their surrounding communities, and away from centralized power monopolies. More than any other plant on Earth, hemp holds the promise of a sustainable ecology and economy.

If all fossil fuels and their derivatives, as well as trees for paper and construction were banned in order to save the planet, reverse the Greenhouse Effect and stop deforestation;

Then there is only one known annually renewable natural resource that is capable of providing the overall majority of the world's paper and textiles; meeting all of the world's transportation, industrial and home energy needs, while simultaneously reducing pollution, rebuilding the soil, and cleaning the atmosphere all at the same time . . .

And that substance is - the same one that did it all before - Cannabis Hemp . . . Marijuana!

So, when the young pilot, George Bush, baled out of his burning airplane after a battle over the Pacific, little did he know: -

Parts of his aircraft engine were lubricated with cannabis hempseed oil;

- 100 percent of his life-saving parachute webbing was made from U.S. grown cannabis hemp;

- Virtually all the rigging and ropes of the ship that pulled him in were made of cannabis hemp.

- The fire hoses on the ship (as were those in the schools he had attended) were woven from cannabis hemp; and,

- Finally, as young George Bush stood safely on the deck, his shoes' durable stitching was of cannabis hemp, as it is in all good leather and military shoes to this day.

Yet Bush has spent a good deal of his career eradicating the cannabis plant and enforcing laws to make certain that no one will learn this information - possibly including himself. . .

(USDA film, Hemp for Victory, 1942; U. of KY Agricultural Ext. Service Leaflet 25, March 1943; Galbraith, Gatewood, Kentucky Marijuana Feasibility Study, 1977.)

Henry Timken, a wealthy industrialst and investor of the roller bearing, got wind of Schlichten's invention and went to meet the inventor in February of 1917. Timken saw the decorticator a a revolutionary discovery that would improve conditions for mankind. Timken offered Schlichten the chance to grow 100 acres of hemp on his ranch in the fertile farmlands of Imperial Valley, California, just east of San Diego, so that Schlichten could test his invention.

Shortly thereafter, Timken met with the newspaper giant E.W. Scripps, and his long-time associate Milton McRae, at Miramar, Scripp's home in San Diego. Scripps, then 63, had accumulated the largest chain of newspapers in the country. Timken hoped to interest Scripps in making newsprint from hemphurds.

Turn-of-the-century newspaper barons needed huge amounts of paper to deliver their swelling circulations. Nearly 30% of the four million tons of paper manufactured in 1909 was newsprint; by 1914 the circulation of daily newspapers had increased by 17% over 1909 figures to over 28 million copies.10 By 1917, the price of newsprint was rapidly rising, and McRae, who had been investigating owning a paper mill since 1904,11 was concerned.

McRae quickly became excited about the plan. He called the decorticator "a great invention. . . [which] will not only render great service to this country, but it will be very profitable financially. . . [it] may revolutionize existing conditions." On August 3, as harvest time neared, a meeting was arranged between Schlichten, McRae, and newspaper manager Ed Chase.

Without Schlichten's knowledge, McRae had his secretary record the three-hour meeting stenographically. The resulting document, the only known record of Schlichten's voluminous knowledge found to date, is reprinted fully in Appendix I.

Schlichten had thoroughly studied many kinds of plants used for paper, among them corn, cotton, yucca, and Espana bacata. Hemp, it seemed, was his favorite:

"The hemp hurd is a practical success and will make paper of a higher grade than ordinary news stock," he stated.

His hemp paper was even better than that produced for USDA Bulletin 404, he claimed, because the decorticator eliminated the retting process, leaving behind short fibers and a natural glue that held the paper together.

At 1917 levels of hemp production Schlichten anticipated making 50,000 tons of paper yearly at a retail price of $25 a ton. This was less than 50 percent of the price of newsprint at the time! And every acre of hemp turned to paper, Schlichten added, would preserve five acres of forest.

McRae was very impressed by Schlichten. The man who dined with presidents and captains of industry wrote to Timken, "I want to say without equivocation that Mr. Schlichten impressed me as being a man of great intellectuality and ability; and so far as I can see, he has created and constructed a wonderful machine." He assigned Chase to spend as much time as he could with Schlichten and prepare a report.

Scripps, on the other hand, was not in an optimistic frame of mind. He had lost faith in a government that he believed was leading the country to financial ruin because of the war, and that would take 40 percent of his profits in income tax. In an August 14 letter to his sister, Ellen, he said: "When Mr. McRae was talking to me about the increase in the price of white paper that was pending, I told him I was just fool enough not to be worried about a thing of that kind." The price of paper was expected to rise 50 percent, costing Scripps his entire year's profit of $1,125,000! Rather than develop a new technology, he took the easy way out: the Penny Press Lord simply planned to raise the price of his papers from one cent to two cents.

Chase witnessed the decorticator produce seven tons of hemp hurds in two days. At full production, Schlichten anticipated each machine would produce five tons per day. Chase figured hemp could easily supply Scripps' West Coast newspapers, with leftover pulp for side businesses. He estimated the newsprint would cost between $25 and $35 per ton, and proposed asking an East Coast paper mill to experiment for them.

McRae, however, seems to have gotten the message that his boss was no longer very interested in making paper from hemp. His response to Chase's report is cautious: "Much will be determined as to the practicability by the cost of transportation, manufacture, etc., etc., which we cannot ascertain without due investigation." Perhaps when his ideals met with the hard work of developing them, the semi-retired McRae backed off.

By September, Timken's crop was producing one ton of fiber and four tons of hurds per acre, and he was trying to interest Scrips in opening a paper mill in San Diego. McRae and Chase travelled to Cleveland and spent to hours convincing Timken that, while hemp hurds were usable for other types of paper, they could not be made into newsprint cheaply enough. Perhaps the eastern mill at which they experimented wasn't encouraging - after all, it was set up to make wood pulp paper.

By this time, Timken, too, was hurt by the wartime economy. He expected to pay 54 percent income tax and was trying to borrow $2 million at 10 percent interest to retool for war machines. The man who a few weeks earlier could not wait to get to California no longer expected to go west at all that winter. He told McRae, "I think I will be too damn busy in this section of the country looking after business."

The decorticator resurfaced in the 1930's, when it was touted as the machine that would make hemp a "Billion Dollar Crop" in articles in Mechanical Engineering and Popular Mechanics.* (Until the 1993 edition of The Emperor, the decorticator was believed to be a new discovery at that time.) Once again, the burgeoning hemp industry was halted, this time by the Marijuana Tax Act of 1937.

Ellen Komp A fuller account of the story 12 may be found in the Appendix.

First, we introduced ourselves and told him we were writing for Green political party newspapers. Then we asked Rawlings, "If you could have any choice, what would be the ideal way to stop or reverse the Greenhouse Effect?"

He said, "Stop cutting down trees and stop using fossil fuels."

"Well, why don't we?"

"There's no viable substitute for wood for paper, or for fossil fuels."

"Why don't we use an annual plant for paper and for fossil fuels?"

"Well, that would be ideal," he agreed. "Unfortunately, there is nothing you can use that could produce enough materials."

"Well, what would you say if there was such a plant that could substitute for all wood pulp paper, all fossil fuels, would make most of our fibers naturally, make everything from dynamite to plastic, grows in all 50 states and that one acre of it would replace 4.1 acres of trees, and that if you used about 6 percent of the U.S. land to raise it as an energy crop - even on our marginal lands, this plant would produce all 75 quadrillion billion B.T.U's needed to run America each year? Would that help save the planet?

"That would be ideal. But there is no such plant."

"We think there is."

"Yeah? What is it?"

"Hemp."

"Hemp! he mused for a moment. "I never would have thought of it. . . You know, I think you're right. Hemp could be the plant that could do it. Wow! That's a great idea!"

We were excited as we outlined this information and delineated the potential of hemp for paper, fiber, fuel, food, paint, etc., and how it could be applied to balance the world's ecosystems and restore the atmosphere's oxygen balance with almost no disruption of the standard of living to which most Americans have become accustomed.

In essence, Rawlings agreed that our information was probably correct and could very well work.

He said, "It's a wonderful idea, and I think it might work. But, of course, you can't use it."

"You're kidding!" we responded.

"Why not?"

"Well, Mr. Herer, did you know that hemp is also marijuana?"

"Yes, of course I know, I've been writing about it for about 40 hours a week for the past 17 years."

"Well, you know marijuana's illegal, don't you? You can't use it."

"Not even to save the world?"

"No. It's illegal", he sternly informed me. "You cannot use something illegal."

"Not even to save the world?" we asked, stunned.

"No, not even to save the world. It's illegal. You can't use it. Period." "Don't get me wrong. It's a great idea," he went on, "but they'll never let you do it."

"Why don't you go ahead and tell the Secretary of Agriculture that a crazy man from California gave you documentation that showed hemp might be able to save the planet and that your first reaction is that he might be right and it needs some serious study. What would he say?"

"Well, I don't think I'd be here very long after I did that. After all, I'm an officer of the government."

"Well, why not call up the information on your computer at your own USDA library. That's where we got the information in the first place."

He said, "I can't sign out that information."

"Well, why not? We did." "Mr. Herer, you're a citizen. You can sign out for anything you want."

"But I am an officer of the Department of Agriculture. Someone's going to want to know why I want all this information. And then I'll be gone."

Finally, we agreed to send him all the information we got from the USDA library, if he would just look at it.

He said he would, but when we called back a month later, he said that he still had not opened the box that we sent him and that he would be sending it back to us unopened because he did not want to be responsible for the information, now that the Bush Administration was replacing him with its own man.

We asked him if he would pass on the information to his successor, and he replied, "Absolutely not."

In May, 1989, we had virtually the same conversation and result with his cohort, Dr. Gary Evans of the U.S. Department of Agriculture and Science, the man in charge of stopping the global warming trend.

In the end, he said, "If you really want to save the planet with hemp, then you [hemp/marijuana activists] would find a way to grow it without the narcotic (sic) top - and then you can use it."

This is the kind of frightened (and frightening) irresponsibility we're up against in our government.

As early as 1901 and continuing to 1937, the U.S. Department of Agriculture repeatedly predicted that, once machinery capable of harvesting, stripping and separating the fiber from the pulp was invented or engineered, hemp would again the America's number one farm crop. The introduction of G.W. Schlichten's decorticator in 1917 nearly fulfilled this prophesy. (See pages 13- 15 and Appendix.)

The prediction was reaffirmed in the popular press when Popular Mechanics published its February, 1938 article, "Billion-Dollar Crop."The first reproduction of this article in over 50 years was in the original edition of this book. The article is reproduced here exactly as it was printed in 1938.

Because of the printing schedule and deadline, Popular Mechanics prepared this article in Spring of 1937 when cannabis hemp for fiber, paper, dynamite and oil, was still legal to grow and was, in fact, and incredibly fast-growing industry.

Also reprinted in this chapter is an excerpt from the Mechanical Engineering article about hemp, published the same month. It originated as a paper presented a year earlier at the February 26, 1937 Agricultural Processing Meeting of the American Society of Mechanical Engineers, New Brunswick, New Jersey.

Reports from the USDA during the 1930's, and Congressional testimony in 1937, showed that cultivated hemp acreage had been doubling in size in America almost every year from the time it hit its bottom acreage, 1930 - when 1,000 acres were planted in the U.S. - to 1937 - when 14,000 acres were cultivated - with plans to continue to double that acreage annual in the foreseeable future.

As you will see in these articles, the newly mechanized cannabis hemp industry was in its infancy, but well on its way to making cannabis America's largest agricultural crop. And, in light of subsequent developments (e.g. biomass energy technology, building materials, etc.), we now know that hemp is the world's most important ecological resource and therefore, potentially our planet's single largest industry.

The Popular Mechanics article was the very first time in American history that the term "billion-dollar"* was ever applied to any U.S. agricultural crop!

*Equivalent to $40-$80 billion now.

Experts today conservatively estimate that, once fully restored in America, hemp industries will generate $500 billion to a trillion dollars per year, and will save the planet and civilization from fossil fuels and their derivatives - and from deforestation!

If Harry Anslinger, DuPont, Hearst and their paid-for (know it or not, then as now) politicians had not outlawed hemp - under the pretext of marijuana (see Chapter Four, "Last Days of Legal Cannabis") - and suppressed hemp knowledge from our schools, researchers and even scientists; the glowing predictions in these articles would already have come true by now - and more benefits than anyone could then envision - as new technologies and uses continue to develop.

As one colleague so aptly put it: "These articles were the last honest word spoken on hemp's behalf for over 40 years..."

2. Ibid.

3. Diaries of George Washington; Writings of George Washington, Letter to Dr. James Anderson, May 26, 1794, vol. 33, p. 433, (U.S. govt. pub., 1931); Letters to his caretaker, Williams Pearce, 1795 & 1796; Thomas Jefferson, Jefferson's Farm Books, Abel, Ernest, Marijuana: The First 12,000 Years, Plenum Press, NY, 1980; M. Aldrich, et al.

2. Ibid.

3. Levi-Strauss & Company of San Francisco, CA, author's personal communication with Gene McClaine, 1985.

4. Ye Olde Spinning Jennys and Wheels were principally used for fiber inthis order: cannabis hemp, flax, wool, cotton, and so forth.

5. Frazier, Jack, The Marijuana Farmers, Solar Age Press, New Orleans, LA, 1974; U.S. Library of congress; National Archives; U.S. Mint; etc.

6. Adams, James T., editor, Album of American History, Charles Scribner's Sons, NY, 1944, g. 116.

7. Frazier, Jack, The Marijuana Farmers, Solar Age Press, New Orleans, LA, 1974; U.S. Library of Congress; National Archives.

8. Sloman, Larry, Reefer Madness, Grove, New York, NY, 1979, pg. 72.

9. Bonnie, Richard and Whitebread, Charles, The Marijuana Conviction, Univ. of Virginia Press, 1974.

10. World Almanac, 1914, p. 225; 1917.

11. Forty Years in Newspaperdom, Milton McRae, 1924 Brentano's NY

12. Scripps Archives, University of Ohio, Athens, and Ellen Browing Scripps Archives, Denison Library, Claremont College, Claremont, California

What we (the colonial Americans) and the rest of the world used to make all our paper from was the discarded sails and ropes by ship owners as scrap for recycling into paper.

The rest of our paper came from our worn-out clothes, sheets, diapers, curtains and rags* sold to scrap dealers made primarily from hemp and sometimes flax.

*Hence the term "rag paper."

Our ancestors were too thrifty to just throw anything away, so, until the 1880's, any remaining scraps and clothes were mixed together and recycled into paper.

It is generally believed by scholars that the early Chinese knowledge, or art, of hemp paper making (1st Century A.D. - 800 years before Islam discovered how, and 1,200 to 1,400 years before Europe) was one of the two chief reasons that Oriental knowledge and science were vastly superior to that of the West for 1,400 years. Thus, the art of long-lasting hemp paper making allowed the Orientals' accumulated knowledge to be passed on, built upon, investigated, refined, challenged and changed, for generation after generation (in other words, cumulative and comprehensive scholarship).

The other reason that Oriental knowledge and science sustained superiority to that of the West for 1,400 years was that the Roman Catholic Church forbade reading and writing for 95% of Europe's people; in addition, they burned, hunted down, or prohibited all foreign or domestic books - including their own Bible! - for over 1,200 years under the penalty and often-used punishment of death. Hence, many historians term this period "The Dark Ages" (476 A.D. - 1000 A.D., or even until the Renaissance). (See Chapter 10 on Sociology.) [So the Dark Ages has origin in the Church,that sounds right to me D.C]

Rope, Twine & Cordage

Virtually every city and town (from time out of mind) in the world had an

industry making hemp rope.6 Russia, however, was the world's largest

producer and best-quality manufacturer, supplying 80 percent of the Western

world's hemp from 1740 until 1940. Thomas Paine outlined four essential natural resources for the new nation in Common Sense (1776); "cordage, iron, timber and tar."

Chief among these was hemp for cordage. He wrote, "Hemp flourishes even to rankness, we do not want for cordage." Then he went on to list the other essentials necessary for war with the British navy; cannons, gunpowder, etc.

From 70-90% of all rope, twine, and cordage was made from hemp until 1937. It was then replaced mostly by petrochemical fibers (owned principally by DuPont under license from Germany's I.G. Corporation patents) and by Manila (Abaca) Hemp, with steel cables often intertwined for strength - brought in from our "new" far-western Pacific Philippines possession, seized from Spain as reparation for the Spanish American War in 1898.

Art Canvas

Hemp is the perfect archival medium. 7 The paintings of Van Gogh, Gainsborough, Rembrandt, etc., were primarily painted on hemp canvas, as were practically all canvas paintings.

A strong, lustrous fiber, hemp withstands heat, mildew, insects and is not damaged by light. Oil paintings on hemp and/or flax canvas have stayed in fine condition for centuries.

Paints & Varnishes

For thousands of years, virtually all good paints and varnishes were made with

hemp seed oil and/or linseed oil.

For instance, in 1935 alone, 116 million pounds (58,000) tons*) of hemp seed

were used in America just for paint and varnish. The hemp drying oil business

went principally to DuPont petrochemicals.8 *National Institute of Oilseed Products congressional testimony against the 1937 Marijuana Transfer Tax Law. As a comparison, consider that the U.S. Drug Enforcement Administration (DEA), along with all America's state and local police agencies, claim to have seized for all of 1996, 700+ tons of American-grown marijuana; seed, plant, root, dirt clum and all. Even the DEA itself admits that 94 to 97 percent of all marijuana/hemp plants that have been seized and destroyed since the 1960's were growing completely wild and could not have been smoked as marijuana.

Congress and the Treasury Department were assured through secret testimony given by DuPont in 1935-37 directly to Herman Oliphant, Chief Counsel for the Treasury Dept., that hempseed oil could be replaced with synthetic petrochemical oils made principally by DuPont.

Oliphant was solely responsible for drafting the Marijuana Tax Act that was submitted to Congress.9 (See complete story in Chapter 4, "The Last Days of Legal Cannabis.")

Lighting Oil

Until about 1800, hempseed oil was the most consumed lighting oil in

America and the world. From then until the 1870's, it was the second most

consumed lighting oil, exceeded only by whale oil. Hempseed oil lit the lamps of legendary Aladdin, Abraham the prophet, and in real life, Abraham Lincoln. It was the brightest lamp oil.

Hempseed oil for lamps was replaced by petroleum, kerosene, etc., after the 1859 Pennsylvania oil discovery and John D. Rockefeller's 1870-on national petroleum stewardship. (See chapter nine of "Economics.")

In fact, the celebrated botanist Luther Burbank stated, "The seed [of cannabis] is prized in other countries for its oil, and its neglect here illustrates the same wasteful use of our agricultural resources."

(Burbank, Luther, How Plants Are Trained To Work For Man, Useful Plants, P.F. Collier & Son Co., NY, Vol. 6, pg. 48.)

Biomass Energy

In the early 1900's, Henry Ford and other futuristic, organic, engineering

geniuses recognized (as their intellectual, scientific heirs still do today) an

important point - that up to 90 percent of all fossil fuel used in the world today

(coal, oil, natural gas, etc.) should long ago have been replaced with biomass

such as: cornstalks, cannabis, waste paper and the like. Biomass can be converted to methane, methanol or gasoline at a fraction of the current cost of oil, coal, or nuclear energy - especially when environmental costs are factored in - and its mandated use would end acid rain, end sulfur based smog, and reverse the Greenhouse Effect on our planet - right now!* *Government and oil and coal companies, etc., will insist that burning biomass fuels is no better than using up our fossil fuel reserves, as far as pollution goes; but this is patently untrue.

Why? Because, unlike fossil fuels, biomass comes from living (not extinct) plants that continue to remove carbon dioxide pollution from our atmosphere as they grow, through photosynthesis. Furthermore, biomass fuels do not contain sulfur.

This can be accomplished if hemp is grown for biomass and then converted through pyrolysis (charcoalizing) or biochemical composting into fuels to replace fossil fuel energy products.*

*Remarkably, when considered on a planet-wide, climate-wide, soil-wide basis, cannabis is at least four and possibly many more times richer in sustainable, renewable biomass/cellulose potential than its nearest rivals on the planet - cornstalks, sugarcane, kenaf trees, ect. (Solar Gas, 1980; Omni, 1983; Cornell University; Science Digest, 1983; etc.).

Also see Chapter 9 on "Economics."

One product of pyrolysis, methanol, is used today by most race cars and was used by American farmers and auto drivers routinely with petroleum/methanol options starting in the 1920's, through the 1930's, and even into the mid-1940's to run tens of thousands of auto, farm and military vehicles until the end of World War II.

Methanol can even be converted to a high-octane lead-free gasoline using a catalytic process developed by Georgia Tech University in conjunction with Mobil Oil Corporation.

Medicine

From 1842 through the 1890's, extremely strong marijuana (then known as

cannabis extractums) and hashish extracts, tinctures and elixirs were routinely

the second and third most-used medicines in America for humans (from birth,

through childhood, to old age) and in veterinary medicine until the 1920's and

longer. (See Chapter 6 on "Medicine," and Chapter 13 on the "19th Century.") As stated earlier, for at least 3,000 years, prior to 1842, widely varying marijuana extracts (buds, leaves, roots, etc.) were the most commonly used and widely accepted majority of mankind's illnesses.

However, in Western Europe, the Roman Catholic Church forbade use of cannabis or any medical treatment, except for alcohol or blood letting, for 1200-plus years. (See Chapter 10 on "Sociology.")

The U.S. Pharmacopoeia indicated that cannabis should be used for treating such ailments as: fatigue, fits of coughing, rheumatism, asthma, delirium tremens, migraine headaches and the cramps and depressions associated with menstruation.(Professor William EmBoden, Professor of Narcotic Botany, California State University, Northridge.)

Queen Victoria used cannabis resins for her menstrual cramps and PMS, and her reign (1837-1901) paralleled the enormous growth of the use of Indian cannabis medicine in the English-speaking world.

In this century, cannabis research has demonstrated therapeutic value - and complete safety - in the treatment of many health problems including asthma, glaucoma, nausea, tumors, epilepsy, infection, stress, migraines, anorexia, depression, rheumatism, arthritis and possible herpes. (See Chapter 7, "Therapeutic Uses of Cannabis.")

Food Oils & Protein

Hempseed was regularly used in porridge, soups, and gruels by virtually all the

people of the world up until this century. Monks were required to eat

hempseed dishes three times a day, to weave their clothes with it and to print

their Bibles on paper made with its fiber. (See Rubin, Dr. Vera, "Research Institute for the Study of Man;" Eastern Orthodox Church; Cohen & Stillman, Therapeutic Potential of Marijuana, Plenum Press, 1976; Abel, Ernest, Marijuana, The First 12,000 Years, Plenum Press, NY, 1980; Encyclopedia Brittanica.)

Hempseed can be pressed for its highly nutritious vegetable oil, which contains the highest amount of essential fatty acids in the plant kingdom. These essential oils are responsible for our immune responses and clear the arteries of cholesterol and plaque.

The byproduct of pressing the oil from the seed is the highest quality protein see cake. It can be sprouted (malted) or ground and baked into cakes, breads and casseroles. Marijuana seed protein is one of mankind's finest, most complete and available-to-the-body vegetable proteins. Hempseed is the most complete single food source for human nutrition. (See discussion of edistins and essential fatty acids, Chapter 8.)

Hempseed was - until the 1937 prohibition law - the world's number-one bird seed, for both wild and domestic birds. It was their favorite* of any seed food on the planet; four million pounds of hempseed for songbirds were sold at retail in the U.S. in 1937. Birds will pick hempseeds out and eat them first from a pile of mixed seed. Birds in the world live longer and breed more with hempseed in their diet, using the oil for their feathers and their overall health. (More in Chapter 8, "Hemp as a Basic World Food.")

*Congressional testimony, 1937; "Song birds won't sing without it," the bird food companies told Congress. Result; sterilized cannabis seeds continue to be imported into the U.S. from Italy, China and other countries.

Hempseed produces no observable high for humans or birds. Only the most minute traces of THC are in the seed. Hempseed is also the favorite fish bait in Europe. Anglers buy pecks of hempseed at bait stores, then thrashing for the hempseed and are caught by hook. No other bait is as effective, making hempseed generally the most desirable and most nutritious food for humans, birds and fish.

(Jack Herer's personal research in Europe.) (Frazier, Jack, The Marijuana Farmers, Solar Age Press, New Orleans, LA, 1972)

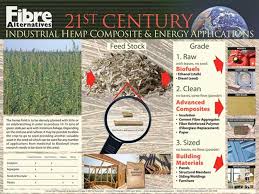

Building Materials & Housing

Because one acre of hemp produces as much cellulose fiber pulp as 4.1 acres

of trees,* hemp is the perfect material to replace trees for pressed board,

particle board and for concrete construction molds. *Dewey & Merrill, Bulletin #404, United States Dept. of Agriculture, 1916.

Practical, inexpensive fire-resistant construction material, with excellent thermal and sound-insulating qualities, is made by heating and compressing plant fibers to create strong construction paneling, replacing dry wall and plywood. William B. Conde of Conde's Redwood Lumber, Inc. near Eugene, Oregon, in conjunction with Washington State University (1991-1993), has demonstrated the superior strength, flexibility, and economy of hemp composite building materials compared to wood fiber, even as beams.

Isochanvre, a rediscovered French building material made from hemp hurds mixed with lime, actually petrifies into a mineral state and lasts for many centuries. Archeologists have found a bridge in the south of France, from the Merovingian period (500-751 A.D.), built with this process. (See Chenevotte habitat of Rene, France in Appendix I.)

Hemp has been used throughout history for carpet backing. Hemp fiber has potential in the manufacture of strong, rot resistant carpeting - eliminating the poisonous fumes of burning synthetic materials in a house or commercial fire, along with allergic reactions associated with new synthetic carpeting.

Plastic plumbing pipe (PVC pipes) can be manufactured using renewable hemp cellulose as the chemical feedstocks, replacing non-renewable coal or petroleum-based chemical feedstocks.

So we can envision a house of the future built, plumbed, painted and furnished with the world's number-one renewable resource - hemp.

Smoking, Leisure & Creativity

The American Declaration of Independence recognizes the "inalienable rights"

of "life, liberty and the pursuit of happiness." Subseuqent court decisions have

inferred the rights to privacy and choice from this, the U.S. Constitution and

its Amendments. Many artists and writers have used cannabis for creative stimulation - from the writers of the world's religious masterpieces to our most irreverent satirists. These include Lewis Carroll and his hookah- smoking caterpillar in Alice in Wonderland, plus Victor Hugo and Alexander Dumas; such jazz greats as Louis Armstrong, Cab Calloway, Duke Ellington and Gene Krupa; and the pattern continues right up to modern-day artists and musicians such as the Beatles, the Rolling Stones, the Eagles, the Doobie Brothers, Bob Marley, Jefferson Airplane, Willie Nelson, Buddy Rich, Country Joe & the Fish, Joe Walsh, David Carradine, David Bowie, Iggy Pop, Lola Falana, Hunter S. Thompson, Peter Tosh, the Grateful Dead, Cypress Hill, Sinead O'Connor, Black Crowes, etc.

Of course, smoking marijuana only enhances creativity for some and not for others.

But throughout history, various prohibition and "temperance" groups have attempted and occasionally succeeded in banning the preferred recreational substances of others, like alcohol, tobacco or cannabis.

Abraham Lincoln responded to this kind of repressive mentality in December, 1840, when he said:

"Prohibition . . . goes beyond the bounds of reason in that it attempts to control a man's appetite by legislation and makes a crime out of things that are not crimes . . . A prohibition law strikes a blow at the very principles upon which our government was founded.

Economic Stability, Profit & Free Trade

We believe that in a competitive market, with all facts known, people will rush

to buy long-lasting, biodegradable "Pot Tops" or "Mary Jeans," etc., made

from a plant without pesticides or herbicides. Some of the companies who

have led the way with these products are Ecolution, Hempstead, Marie Mills,

Ohio Hempery, Two Star Dog, Headcase, and in Germany, HanfHaus, et al. It's time we put capitalism to the test and let the unrestricted market of supply and demand as well as "Green" ecologically consciousness decide the future of the planet.

A cotton shirt in 1776 cost $100 to $200, while a hemp shirt cost 50 cents to $1. By the 1830's, cooler, lighter cotton shirts were on par in price with the warmer, heavier, hempen shirts, providing a competitive choice.

People were able to choose their garments based upon the particular qualities they wanted in a fabric. Today we have no such choice.

The role of hemp and other natural fibers should be determined by the market of supply and demand and personal tastes and values, not by the undue influence of prohibition laws, federal subsidies and huge tariffs that keep the natural fabrics from replacing synthetic fibers.

Sixty years of government suppression of information has resulted in virtually no public knowledge of the incredible potential of the hemp fiber or its uses.

By using 100% hemp or mixing hemp with cotton, you will be able to pass on your shirts, pants and other clothing to your grandchildren. Intelligent spending could essentially replace the use of petrochemical synthetic fibers such as nylon and polyester with tougher, cheaper, cool, absorbent, breathing, biodegradable, natural fibers.

China, Italy and Eastern European countries such as Hungary, Romania, Czechoslovakia, Poland, and Russia currently make millions of dollars worth of sturdy hemp and hemp/cotton textiles - and could be making billions of dollars worth - annually.

These countries build upon their traditional farming and weaving skills, while the U.S. tries to force the extinction of this plant to prop up destructive synthetic technologies.

Even cannabis/cotton blend textiles were still not cleared for direct sale in the U.S. until 1991. The Chinese, for instance, were forced by tacit agreement to send us inferior ramie/cottons.

(National Import/Export Textile Company of Shangai, Personal communication with author, April and May, 1983.)

As the 1990 edition of The Emperor went to press, garments containing at least 55 percent cannabis hemp arrived from China and Hungary. In 1992, as we went to press, many different grades of 100 percent hemp fabric had arrived directly from China and Hungary. Now, in 1998, hemp fabric is in booming demand all over the world, arriving from Romania, Poland, Italy, Germany, et al. Hemp has been recognized as the hottest fabric of the 1990's by Rolling Stone, Time, Newsweek, Paper, Detour, Details, Mademoiselle, The New York Times, The Los Angeles Times, Der Spiegel, ad infinitum. All have run, over and over again, major stories on industrial and nutritional hemp.

Additionally, hemp grown for biomass could fuel a trillion-dollar per year energy industry, while improving air quality and distributing the wealth to rural areas and their surrounding communities, and away from centralized power monopolies. More than any other plant on Earth, hemp holds the promise of a sustainable ecology and economy.

In Conclusion . . .

We must reiterate our original premise with our challenge to the world to

prove us wrong: If all fossil fuels and their derivatives, as well as trees for paper and construction were banned in order to save the planet, reverse the Greenhouse Effect and stop deforestation;

Then there is only one known annually renewable natural resource that is capable of providing the overall majority of the world's paper and textiles; meeting all of the world's transportation, industrial and home energy needs, while simultaneously reducing pollution, rebuilding the soil, and cleaning the atmosphere all at the same time . . .

And that substance is - the same one that did it all before - Cannabis Hemp . . . Marijuana!

When Hemp Saved George Bush's Life

One more example of the importance of hemp: Five years after cannabis hemp

was outlawed in 1937, it was promptly reintroduced for the World War II

effort in 1942. So, when the young pilot, George Bush, baled out of his burning airplane after a battle over the Pacific, little did he know: -

Parts of his aircraft engine were lubricated with cannabis hempseed oil;

- 100 percent of his life-saving parachute webbing was made from U.S. grown cannabis hemp;

- Virtually all the rigging and ropes of the ship that pulled him in were made of cannabis hemp.

- The fire hoses on the ship (as were those in the schools he had attended) were woven from cannabis hemp; and,

- Finally, as young George Bush stood safely on the deck, his shoes' durable stitching was of cannabis hemp, as it is in all good leather and military shoes to this day.

Yet Bush has spent a good deal of his career eradicating the cannabis plant and enforcing laws to make certain that no one will learn this information - possibly including himself. . .

(USDA film, Hemp for Victory, 1942; U. of KY Agricultural Ext. Service Leaflet 25, March 1943; Galbraith, Gatewood, Kentucky Marijuana Feasibility Study, 1977.)

The Battle of Bulletin 404

or

How World War I Cost

Us Hemp & the Forests

The Setting

In 1917, the world was battling World War I. In this country, industrialists,

just beset with the minimum wage and graduated income, tax, were sent into a

tailspin. Progressive ideals were lost as the United States took its place on the

world stage in the struggle for commercial supremacy. Is is against this

backdrop that the first 20th Century hemp drama was played.

The Players

The story begins in 1916, soon after the release of USDA Bulletin 404. Near

San Diego, California, a 50-year-old German immigrant named George

Schlichten had been working on a simple yet brilliant invention. Schlichten

had spent 18 years and $400,000 on the decorticator, a machine that could

strip the fiber from nearly any plant, leaving the pulp behind. To build it, he

had developed an encyclopedic knowledge of fibers and paper making. His

desire was to stop the felling of forests for paper, which he believed to be a

crime. His native Germany was well advanced in forestry and Schlichten knew

that destroying forests meant destroying needed watersheds. Henry Timken, a wealthy industrialst and investor of the roller bearing, got wind of Schlichten's invention and went to meet the inventor in February of 1917. Timken saw the decorticator a a revolutionary discovery that would improve conditions for mankind. Timken offered Schlichten the chance to grow 100 acres of hemp on his ranch in the fertile farmlands of Imperial Valley, California, just east of San Diego, so that Schlichten could test his invention.

Shortly thereafter, Timken met with the newspaper giant E.W. Scripps, and his long-time associate Milton McRae, at Miramar, Scripp's home in San Diego. Scripps, then 63, had accumulated the largest chain of newspapers in the country. Timken hoped to interest Scripps in making newsprint from hemphurds.

Turn-of-the-century newspaper barons needed huge amounts of paper to deliver their swelling circulations. Nearly 30% of the four million tons of paper manufactured in 1909 was newsprint; by 1914 the circulation of daily newspapers had increased by 17% over 1909 figures to over 28 million copies.10 By 1917, the price of newsprint was rapidly rising, and McRae, who had been investigating owning a paper mill since 1904,11 was concerned.

Sowing the Seeds

In May, after further meetings with Timkin, Scripps asked McRae to

investigate the possibility of using the decorticator in the manufacture of

newsprint. McRae quickly became excited about the plan. He called the decorticator "a great invention. . . [which] will not only render great service to this country, but it will be very profitable financially. . . [it] may revolutionize existing conditions." On August 3, as harvest time neared, a meeting was arranged between Schlichten, McRae, and newspaper manager Ed Chase.

Without Schlichten's knowledge, McRae had his secretary record the three-hour meeting stenographically. The resulting document, the only known record of Schlichten's voluminous knowledge found to date, is reprinted fully in Appendix I.

Schlichten had thoroughly studied many kinds of plants used for paper, among them corn, cotton, yucca, and Espana bacata. Hemp, it seemed, was his favorite:

"The hemp hurd is a practical success and will make paper of a higher grade than ordinary news stock," he stated.

His hemp paper was even better than that produced for USDA Bulletin 404, he claimed, because the decorticator eliminated the retting process, leaving behind short fibers and a natural glue that held the paper together.

At 1917 levels of hemp production Schlichten anticipated making 50,000 tons of paper yearly at a retail price of $25 a ton. This was less than 50 percent of the price of newsprint at the time! And every acre of hemp turned to paper, Schlichten added, would preserve five acres of forest.

McRae was very impressed by Schlichten. The man who dined with presidents and captains of industry wrote to Timken, "I want to say without equivocation that Mr. Schlichten impressed me as being a man of great intellectuality and ability; and so far as I can see, he has created and constructed a wonderful machine." He assigned Chase to spend as much time as he could with Schlichten and prepare a report.

Harvest Time